Synopsis: As a hand-tool woodworker, Josh Klein loves the smoothness and workability of Jap white pine, and he’s not maintaining that information to himself. From the provision of huge pine boards to the benefit of milling, gentle weight , and shocking sturdiness, white pine has lots to supply. And it’s not exhausting to complete, both, in case you use a few of Klein’s suggestions.

There isn’t a wooden I’d reasonably work than Jap white pine. As a hand-tool woodworker, the flexibility to aircraft a chunky curl off a creamy clean board offers me a way of energy that the majority people don’t affiliate with working by hand. There’s a cause that pine was used so extensively in historic furnishings earlier than the mechanization of the Industrial Revolution: It really works like a dream. The excellent news for us is that these massive timber, although massively diminished within the overharvesting and clear-cutting of the early colonists and the next logging business, are nonetheless round, and so they’re nonetheless as workable, so pine stays an optimum alternative for furnishings, and in addition for having fun with your self within the store.

Broad boards are accessible and cheap

Who doesn’t love huge boards? Visiting historic homes or living-history museums, one of the frequent remarks I overhear from different visitors is how outstanding the huge boards are. It’s not unusual to see boards 20 in. huge in historic houses and furnishings. Particularly after they’re prominently displayed in flooring or tabletops, we are able to’t assist however surprise on the dimension of the tree they got here from. However as exhausting as it’s to imagine, nobody within the 1700s drooled at boards that huge. These boards have been sensible as a result of they have been native, considerable, simple to work, and cheap. Broad boards have been barely greater than the pre-industrial equal of plywood—economical, however not out to impress.

Since moderns like us relish the single-board glory of antiques, it’s noteworthy that to at the present time, huge pine stays comparatively reasonably priced and accessible.

Ease of development

Craftspeople love huge boards for causes aside from their majesty and financial system: Constructing with them is simply so dang fast. When you will have entry to huge inventory, edge jointing is uncommon. This activity is so time-consuming in a hand-tool store that historically craftspeople tried to make use of the widest inventory they might discover. And after they did be part of edges, they weren’t significantly fussy about it. Jointing added a lot labor in planing sq. and straight, gluing, and planing flush, that it’s typical to search out the underside/inside the boards out of aircraft with one another and slathered in hardened glue squeeze-out. This no-nonsense strategy is what furnishings historian Myrna Kaye calls “financial system of labor.” Solely the present floor wanted to look good.

Edge joints require surfacing, jointing the perimeters, gluing, after which resurfacing to flush the boards to one another. In distinction, you probably have a large sufficient board, you possibly can construct a chest out of it with none edge jointing. Take into consideration the time financial savings on a small tabletop made of 1 board: Simply aircraft it and minimize it to dimension. Massive eating tables may be two boards—just one joint. And the labor-saving advantage of huge inventory additionally applies for many who use machines. Nonetheless you’re employed your wooden, in case you’ve ever hung out edge-jointing and gluing up 8-in.-wide boards to make a prime, strive a single-board prime someday. It seems like dishonest.

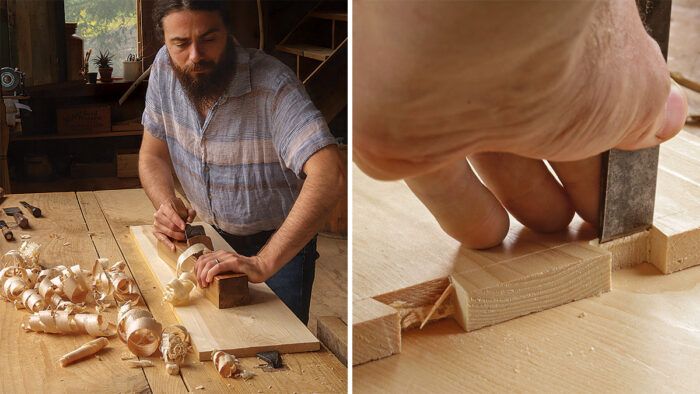

What milling you do have to do is way simpler on pine than hardwoods. Most likely 75% of my planing is completed with a closely set jack aircraft. With this software, I can take quite a few deep bites with out fatigue. Once I work in hardwood, nonetheless, I’ve to take about half as a lot materials per stroke. This distinction provides up significantly by the tip of the challenge. Sawing is quicker, too.

From Tremendous Woodworking #297

To view the whole article, please click on the View PDF button under.

|

Confessions of a Hand-Software Woodworker |

|

Give pine an opportunity |

|

Pine(ing) for perfection |

Obtain FREE PDF